The future of optical measurement system technology

Understanding Just How an Optical Measurement System Improves Accuracy in Industrial Applications

Optical measurement systems play a crucial duty in improving precision across various industrial applications. By leveraging sophisticated innovations such as laser interferometry and 3D imaging sensing units, these systems supply high-resolution, non-contact dimensions. This ability lessens the danger of damaging sensitive elements while ensuring accuracy. The impact of these systems expands beyond mere measurements. Discovering their advantages, applications, and future patterns reveals a complicated landscape of development and challenges that advantages better assessment.

The Basics of Optical Measurement Systems

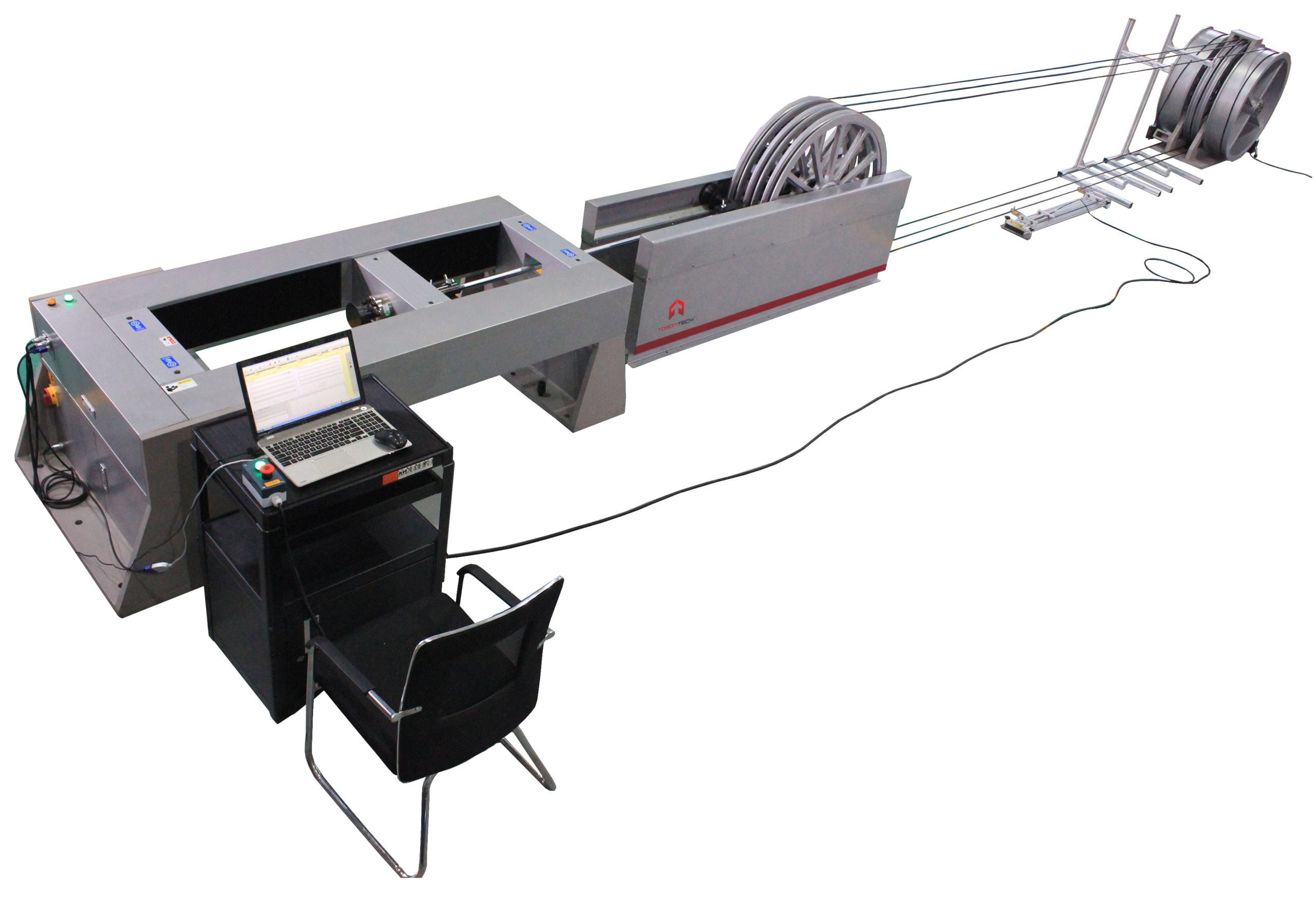

Optical measurement systems function as necessary devices in numerous industrial applications, supplying precise information collection and evaluation. These systems use light as a primary means of measurement, leveraging optical concepts to analyze measurements, settings, and surface attributes of items. They include elements such as lasers, video cameras, and sensors, which function together to catch high-resolution images and information.

The innovation enables non-contact measurements, decreasing the risk of damaging sensitive parts. Optical measurement systems are versatile, discovering utility in quality control, assembly confirmation, and dimensional analysis throughout different markets. They are particularly efficient in settings where typical measurement strategies may fall short, such as determining complex geometries or observing fast movements.

As markets proceed to advance, the integration of optical measurement systems will certainly remain essential for making certain precision and efficiency, eventually improving item high quality and functional productivity in different manufacturing processes.

Trick Technologies Behind Optical Measurement

Secret modern technologies such as laser interferometry strategies and 3D imaging sensing units play an important duty in the efficiency of optical measurement systems (fibre testing equipment). These technologies make it possible for exact measurements and comprehensive analysis in numerous commercial applications. Recognizing their functionalities is important for taking advantage of the complete potential of optical measurement systems

Laser Interferometry Techniques

Many laser interferometry strategies have transformed the field of optical measurement, providing extraordinary precision and precision in numerous industrial applications. These strategies make use of the disturbance of coherent light waves to measure range, variation, and surface irregularities with nanometer-level accuracy. Common techniques include Michelson interferometry, which divides a beam and evaluates stage changes, and Fabry-Pérot interferometry, known for its high resolution in measuring small adjustments. Additionally, laser Doppler interferometry utilizes frequency changes to evaluate velocity, making it important in vibrant dimensions. The flexibility of these methods enables their combination right into varied manufacturing processes, improving quality assurance and making sure adherence to rigid resistances. Consequently, laser interferometry proceeds to play an essential duty beforehand industrial measurement criteria.

3D Imaging Sensors

Developments in measurement technology have actually resulted in the advancement of 3D imaging sensors, which play a substantial function in optical measurement systems. These sensing units record three-dimensional information via numerous techniques such as triangulation, time-of-flight, and organized light. By precisely rebuilding the form and measurements of things, 3D imaging sensors enhance the precision of dimensions in industrial applications. They supply real-time comments, helping with top quality control and ensuring that elements fulfill strict specs. Additionally, their capability to operate in difficult settings, such as varying lights conditions, makes them invaluable in producing processes. As markets progressively embrace automation, the combination of 3D imaging sensing units right into optical measurement systems is expected to drive further improvements in efficiency and precision.

Advantages of Optical Measurement in Market

Although conventional measurement methods have long been the criterion in industrial settings, optical measurement systems supply considerable benefits that boost accuracy and performance. These systems make use of light to record data, leading to high-resolution measurements that are usually unattainable with standard strategies. The non-contact nature of optical dimensions minimizes the danger of damaging sensitive elements during the assessment procedure. Furthermore, the speed of optical dimensions enables rapid data procurement, promoting timely decision-making in hectic industrial atmospheres.

Optical systems are adaptable, efficient in measuring numerous materials and forms without the requirement for comprehensive recalibration. This convenience contributes to boosted process and productivity. Additionally, the automation potential of optical measurement systems decreases human error, making certain regular top quality control. On the whole, the combination of optical measurement technology stands for a modern shift in the direction of boosted accuracy and integrity in commercial procedures, inevitably causing boosted product quality and functional effectiveness.

Applications of Optical Measurement Systems

Optical measurement systems play an essential role in improving manufacturing procedure optimization by providing accurate data for decision-making. These systems ensure quality assurance assurance via real-time tracking and evaluation of production metrics. As sectors significantly take on these innovations, their effect on efficiency and product dependability comes to be go to website apparent.

Production Refine Optimization

Enhancing production procedure efficiency is progressively dependent on the assimilation of optical measurement systems. These systems give real-time data on different parameters, enabling makers to assess procedures with a high degree of accuracy. By allowing specific dimensions of dimensions, surface features, and product buildings, optical measurement systems facilitate the identification of ineffectiveness and bottlenecks in assembly line. The instant comments from these systems equips engineers to make educated decisions, causing enhanced machining, assembly, and ending up procedures. The capability to keep track of conditions constantly allows for flexible changes, reducing downtime and waste. As industries aim for better efficiency and decreased functional prices, optical measurement systems become essential devices for improving production process optimization.

High Quality Control Guarantee

The combination of optical measurement systems greatly wikipedia reference effects quality control guarantee in industrial setups. These systems offer specific and non-destructive measurements, allowing manufacturers to find defects and variances early in the manufacturing process. By making use of sophisticated imaging strategies, such as laser triangulation and interferometry, optical measurement systems ensure that elements fulfill rigid specifications. This promotes real-time monitoring, lowering waste and reducing the threat of faulty products getting to the marketplace. In addition, the information accumulated can be analyzed to refine manufacturing processes additionally, bring about continual renovation. Inevitably, the adoption of optical measurement systems boosts reliability and consistency in quality assurance, promoting higher self-confidence amongst stakeholders and consumers alike in the final items supplied.

Instance Researches: Effective Implementations

Various markets have efficiently incorporated optical measurement systems to enhance their functional performance and item top quality. In the automobile industry, a famous producer embraced a laser triangulation system to keep track of the alignment of vehicle parts. This execution substantially decreased assembly mistakes, causing improved safety and security and minimized costs.

In the aerospace sector, a leading aircraft producer utilized optical metrology for accuracy measurements of generator blades, attaining a reduction in manufacturing tolerances and much better efficiency requirements.

Likewise, a customer electronics company carried out optical measurement technology throughout the manufacturing of smartphone displays, resulting in boosted quality assurance and a decrease in malfunctioning items.

These study highlight how optical measurement systems not only boost accuracy however additionally contribute to general functional effectiveness, demonstrating their value across various fields. By resolving particular needs, these systems have confirmed to be indispensable devices in modern-day industrial applications.

Difficulties and Limitations of Optical Measurement

While optical measurement systems supply substantial advantages in different commercial check my source applications, they are not without their challenges and restrictions. One significant problem is sensitivity to environmental problems, such as temperature changes, moisture, and dirt, which can adversely affect measurement accuracy. Furthermore, optical systems often need exact positioning and calibration, making them prone to human mistake throughout arrangement and procedure. Another constraint is the capacity for interference from ambient light, which can distort dimensions and demand complicated filtering methods. In addition, specific products and surfaces might present difficulties, as reflective or transparent qualities can cause inconsistent readings. The cost of top notch optical parts and systems can additionally be an obstacle for some markets, limiting widespread adoption. Finally, specialized training is often needed for workers to successfully operate and keep these systems, adding to the overall complexity and functional obstacles.

Future Patterns in Optical Measurement Innovation

As developments in modern technology continue to form industrial procedures, the future of optical measurement systems is poised for significant advancement. Emerging patterns indicate a change in the direction of improved combination of man-made intelligence and machine understanding, making it possible for systems to evaluate information in real-time, determine patterns, and improve decision-making procedures. Additionally, the advancement of miniaturized sensing units and advanced optics is expected to bring about more portable and flexible measurement remedies, making them easily accessible for a larger variety of applications.

Additionally, the consolidation of 3D imaging and high-resolution capacities will enable extraordinary precision in measurements, which is vital for sectors such as aerospace and auto. The promote automation and Industry 4.0 will certainly also drive the need for optical measurement systems that can quickly interface with other modern technologies. As these fads unravel, optical measurement systems will likely end up being important to attaining better efficiency and precision across various industrial industries.

Regularly Asked Concerns

How Do Optical Measurement Systems Contrast to Typical Measurement Methods?

Optical measurement systems use higher precision and speed contrasted to standard methods - robotic vision. They decrease human error, boost data collection efficiency, and give real-time results, making them significantly preferred in numerous industrial applications for accurate dimensions

What Industries Benefit one of the most From Optical Measurement Systems?

Optical measurement systems substantially benefit sectors such as aerospace, vehicle, and electronic devices. Their capability to give high-precision measurements boosts quality assurance, decreases manufacturing errors, and enhances total efficiency, making them important in affordable manufacturing environments.

Can Optical Measurement Systems Be Custom-made for Particular Applications?

Optical measurement systems can indeed be personalized for details applications. By adjusting specifications such as wavelength, resolution, and calibration techniques, industries can tailor these systems to fulfill unique precision and precision needs properly.

What Is the Upkeep Demand for Optical Measurement Systems?

The upkeep demands for optical measurement systems usually consist of normal calibration, cleaning of optical components, and software application updates. Sticking to these techniques guarantees accuracy, dependability, and long life of the measurement tools in numerous applications.

How Do Environmental Elements Impact Optical Measurement Precision?

Ecological aspects, such as temperature level variations, moisture, and dirt, substantially impact optical measurement accuracy. These elements can distort light paths and disrupt sensor readings, ultimately compromising the reliability and precision of measurements in commercial settings.